8 Advantages of Using a 3D Printer

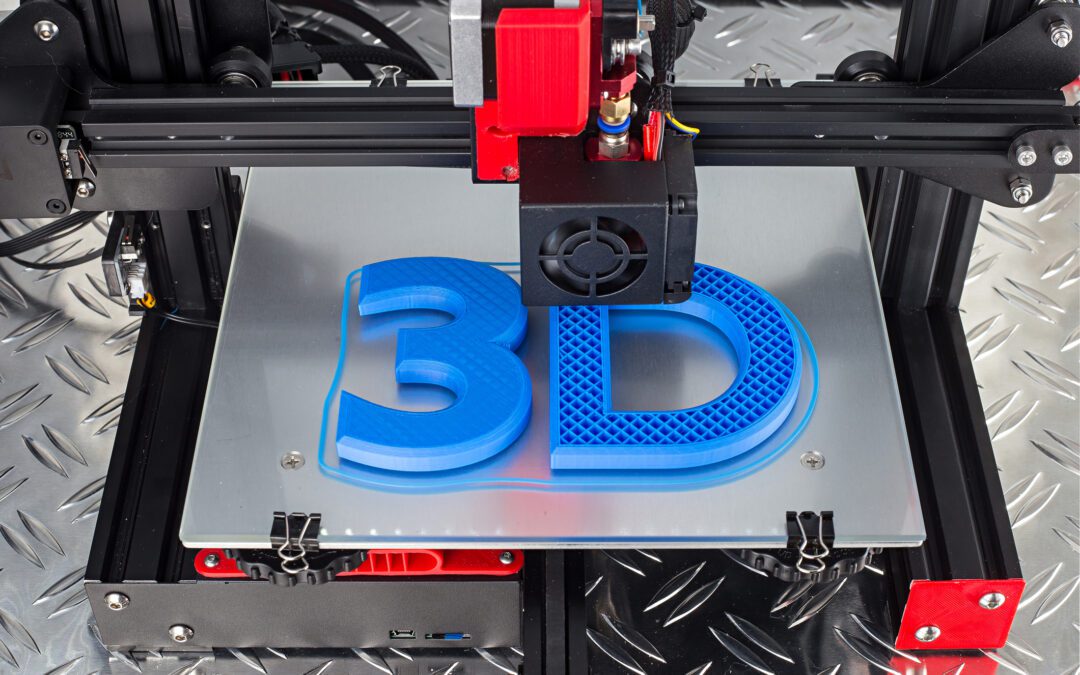

3D printing, also known as additive manufacturing, is a revolutionary technology that enables the creation of three-dimensional objects by sequentially layering material. The creation of 3D-printed objects is achieved using an additive process. This means an object is created by laying down successive layers of material until the object is created. Each layer can be seen as a thinly sliced cross-section of the object. This is fundamentally different from any other existing traditional manufacturing technique. 3D printing is the opposite of subtractive manufacturing, which is the hollowing out of a piece of metal or plastic.

3D printing has gained significant popularity and has the potential to transform various industries by revolutionizing the way products are designed, prototyped, and manufactured.

3D printing typically begins with a digital model or a computer-aided design (CAD) file. This file is sliced into numerous cross-sectional layers, and the 3D printer follows these instructions to create the object layer by layer. The printer deposits material, such as plastic, metal, or composite, in a precise pattern, gradually building up the object until it is complete. The materials used in 3D printing can range from plastics and resins to metals, ceramics, and even living tissue. This article will take a closer look at how a 3D printer works and the advantages of using a 3D printer.

How does a 3D printer work?

A 3D printer uses a layer-by-layer additive manufacturing process to create physical objects from a digital design. While there are different types of 3D printers and variations in the specific printing technologies, the general principles remain similar. Here’s how a typical 3D printer works:

- Digital Design: The process begins with a digital design created using computer-aided design (CAD) software or obtained from a 3D model repository. The design defines the shape and specifications of the object to be printed.

- Slicing: The digital design is then sliced into a series of thin horizontal layers using slicing software. Each layer is represented as a two-dimensional cross-section of the object.

- Material Selection: A suitable printing material is selected Based on the design’s requirements and the desired properties of the final object. Common materials include thermoplastics (e.g., PLA, ABS), metals, resins, ceramics, and even biological materials.

- Preparation: Before printing, the 3D printer needs to be prepared. This typically involves leveling the print bed, ensuring the print surface is clean, and loading the appropriate printing material into the printer’s feeding system.

- Printing Process: Once prepared, the 3D printer starts the printing process. The printer’s software interprets the sliced design file and instructs the printer on depositing material layer by layer to build the object.

a. Layer Deposition: The printer’s extruder or printhead moves along the X, Y, and Z axes according to the instructions from the software. It deposits or melts the printing material onto the print bed or previous layers, adhering it to create the desired shape of the object.

b. Solidification and Bonding: Depending on the printing technology, the material may solidify through cooling (in the case of thermoplastics) or undergo curing or sintering (for resins or metals). This solidification ensures the layers bond, creating a cohesive and structurally sound object.

c. Support Structures: Support structures may sometimes be necessary for overhanging or complex object parts. These structures provide temporary support during printing and are removed later.

- Layer-by-Layer Building: The printer repeats the layer deposition process, stacking one layer on top of another, until the entire object is complete. Each layer adheres to the previous layer, gradually building up the desired shape and structure.

- Finishing and Post-Processing: The object may require post-processing once the printing is finished. This can involve removing support structures, sanding or polishing the surface, applying coatings or finishes, or other steps to achieve the desired final appearance and functionality.

The exact details of the printing process can vary depending on the type of 3D printer technology used. Common technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP), among others. Each technology employs different methods for material deposition, solidification, and layer building, enabling a wide range of applications and material choices in the world of 3D printing.

What are the advantages to using a 3D printer?

There are several advantages associated with 3D printing:

- Design Freedom: 3D printing allows for unparalleled design freedom. It eliminates many of the constraints imposed by traditional manufacturing methods, enabling the creation of complex geometries, intricate details, and customized objects. This freedom promotes innovation and empowers designers to explore new possibilities.

- Rapid Prototyping: 3D printing accelerates the prototyping process significantly. Instead of waiting weeks or months for a prototype to be manufactured, designers can quickly produce physical models and iterate on their designs at a faster pace. This speed saves time and enhances the overall product development cycle. With 3D printing, manufacturers can reduce time to market, produce on demand, and create variations on a per-item basis—amazing for health care products that are customized to the individual patient.

- Cost Efficiency: Traditional manufacturing techniques often involve high setup costs, especially for small production runs or custom-made products. 3D printing eliminates the need for costly molds, tools, and production lines, making it a cost-effective solution for low-volume manufacturing. It also reduces material wastage since only the required amount of material is used.

- On-Demand Manufacturing – the power of now: With 3D printing, products can be manufactured on demand, eliminating the need for large inventories and storage costs. This opens up decentralized manufacturing and localized production possibilities, reducing supply chain complexities and enabling just-in-time production. With 3D printing, you print what you need when you need it.

- Customization and Personalization: 3D printing enables the creation of highly customized and personalized products. It allows for individualization, where each item can be tailored to specific requirements or preferences. This is particularly valuable in healthcare, where customized prosthetics, dental implants, and medical devices can be created for individual patients.

- Complexity without Assembly: 3D printing enables you to produce complex shapes using less material than traditional manufacturing methods. Traditional manufacturing often requires the assembly of multiple parts to create a complex product. In contrast, 3D printing can produce intricate objects as a single piece, eliminating the need for assembly. This simplifies the production process, reduces the risk of parts failing or coming apart, and enhances the overall structural integrity of the object.

- Reduced Waste and Environmental Impact: 3D printing is an inherently sustainable technology. Using only the necessary amount of material and reducing waste helps minimize the environmental impact associated with manufacturing processes. Additionally, localized production can reduce transportation-related emissions and promote more sustainable supply chains.

- Part Consolidation and Lightweighting: 3D printing allows for multiple part assemblies in which weak points and cumbersome fasteners can be printed as one part. Parts that need to be lighter for healthcare, automotive, and aerospace can have a lattice infill or generative design.

While 3D printing has numerous advantages, it also has some limitations, such as slower production speeds for large-scale manufacturing and constraints on certain materials and structural properties. However, ongoing advancements in technology continue to address these limitations and expand the potential applications of 3D printing across various industries, including aerospace, robotics, automotive, healthcare, consumer goods, and architecture.

This innovative technology has unprecedented design freedom. Its tool-less process is energy efficient and affordable, making it accessible to small businesses and even individuals. Nearly anything can be turned into a design and can be 3D printed. These printers are becoming invaluable tools for designers, engineers, and everyday people as they create complex objects such as toys, art, clothing, and pottery, as well as medical tools and implants. We have only just begun to see the ways that 3D printing can make our lives easier and more convenient.

Nota3D helps you navigate the complicated world of 3D printing and software. We help customers select, rent, buy, and repair 3D printers, software, and materials. Our favorite thing is to learn about you and your specific goals when it comes to 3D technology. We have a wide variety of technology and will help you find the right fit. We listen first, until we have a deep understanding of your need—then we get into what solutions are available to solve it.