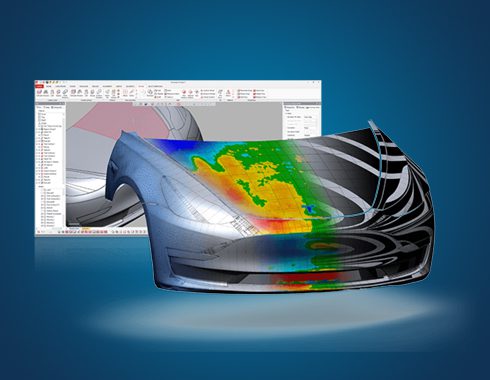

Geomagic Design X

Reverse Engineering Software

Your Fastest Path from Scan to CAD

Reverse engineer physical parts into digital parametric CAD models with the most comprehensive reverse-engineering software, combining history-based CAD with 3D scan data processing.

Geomagic® Design X™ makes it easy to extract new value from existing products by creating CAD models from 3D scans faster, more accurately, and more reliably than any other reverse-engineering method.

- Handles large scan data sets (millions of points) faster than any other reverse-engineering software.

- Creates complex 3D models with hybrid modeling for solid, surface, and mesh.

- Connects directly to your existing CAD environment and creates native files that accurately represent a scanned object.

- Rapidly creates solids or surfaces like you would in CAD.

- Transfers 3D parametric models with full design history directly to popular CAD software.

Why Geomagic Design X?

Fast and accurate

Unlock new ways to accelerate product development for faster time to market, better fit, and longer product life cycles.

Proven and reliable

Don’t leave critical design work to chance with the only software that combines scan processing and CAD plus real-time feedback.

Powerful and flexible

Work seamlessly with any CAD software and create the right model for every project with complete toolsets for solids, surfaces, and meshes.

Easy to learn and use

Start using it right away—works like your CAD software.

What Can You Do with Geomagic Design X?

Geomagic Design X includes features that are purpose-built for converting 3D scan data into high-quality, feature-based CAD models. It does what no other software can with its combination of automatic, guided solid model extraction; incredibly accurate, exact surface fitting to organic 3D scans; mesh editing; and point-cloud processing.

-

- Broadens your design capabilities.

- Enhances your CAD environment.

- Accelerates time to market.

- Leverages existing assets.

- Reduces costs.

It helps you do the impossible. Scan virtually anything and create manufacturing-ready designs.

- Rebuild CAD data for broken tools and molds.

- Recreate non-existent or lost CAD data for parts and molds.

- Design custom products.

- Convert physical parts into CAD for new product designs.

- Make existing parts fit with new parts.

Geomagic Design X supports all major scanners and portable CRMs seamlessly.

Use Geomagic Design X with Geomagic Control X™ 3D inspection and metrology software and Geomagic Wrap® 3D scanning software for a complete, scan-based design and inspection package.