Jewelry 3D Printing

3D Printing

Education Center

Learn More About Jewelry 3D Printing

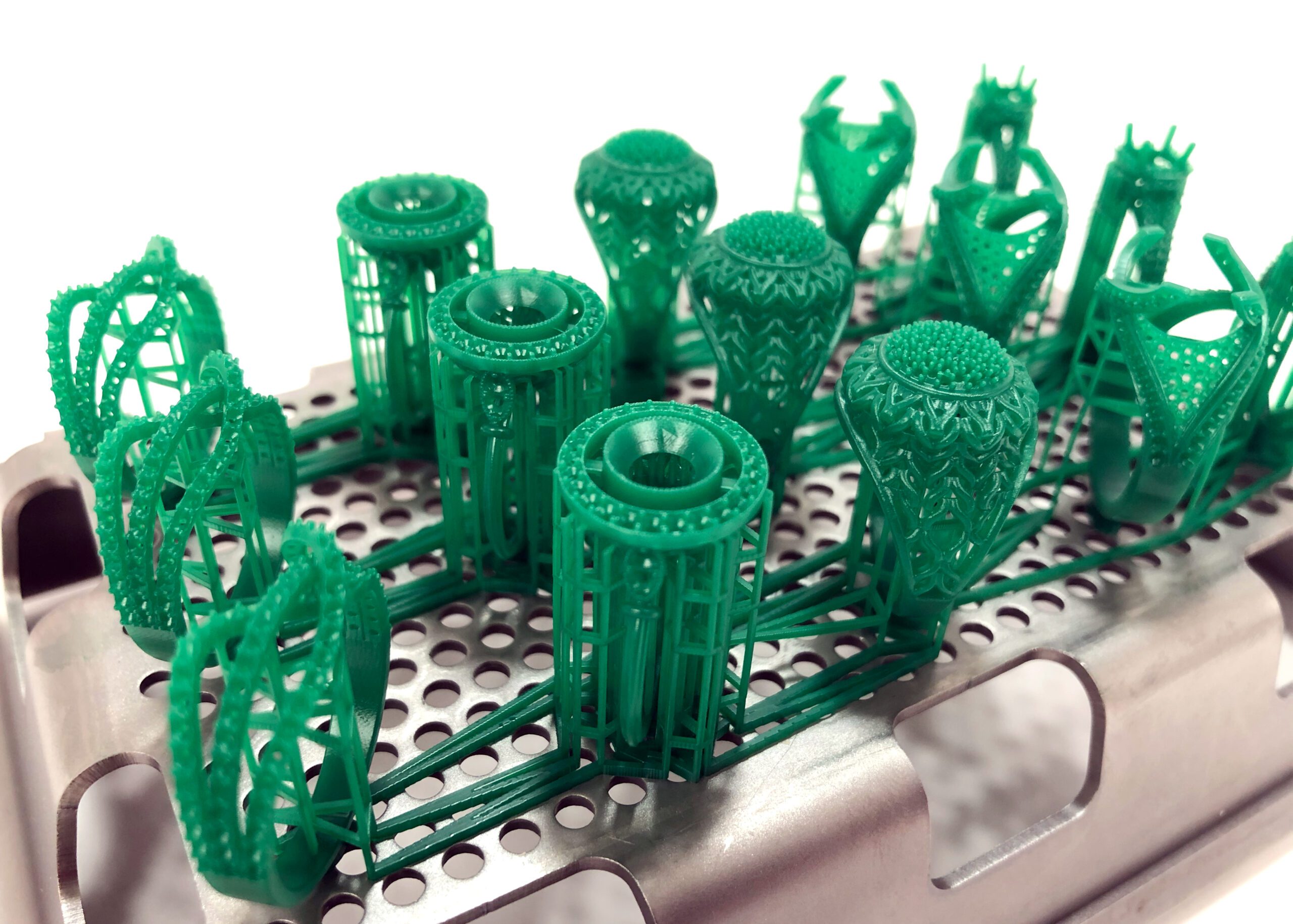

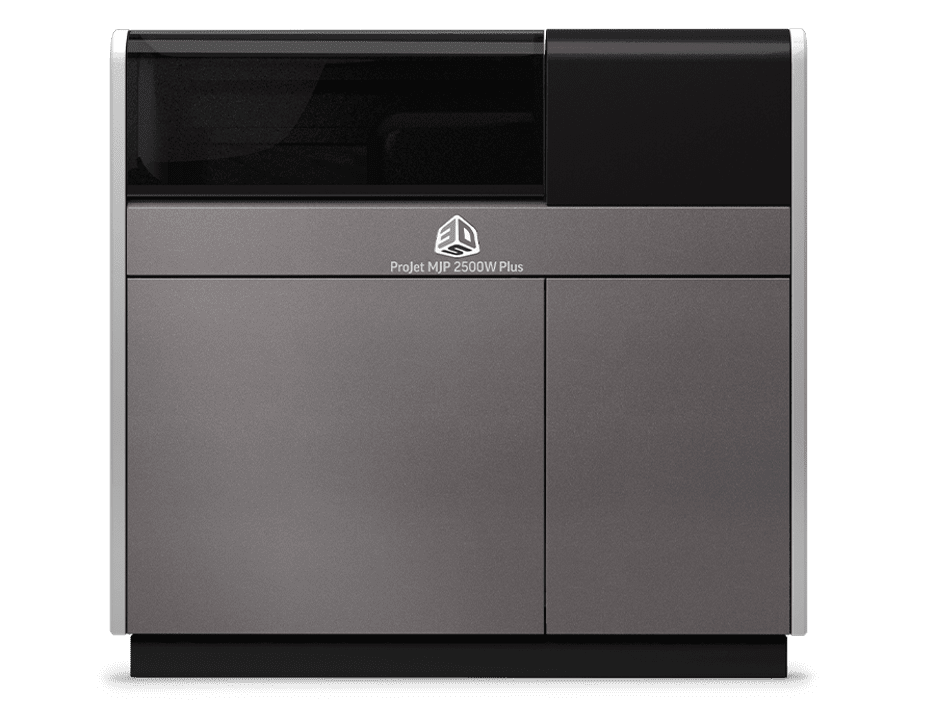

ProJet MJP 2500W Plus

The ProJet® MJP 2500W Plus 3D prints in VisiJet® 100% wax materials to deliver durable, high-quality jewelry patterns for reliable performance and results throughout existing lost-wax casting processes and equipment.

VisiJet wax materials melt like standard casting waxes, with zero ash content for defect-free castings. It is durable for handling and casting fine features, and high contrast colors allow for easy fine details visualization.

Figure 4

Ultra-fast and affordable 3D printing solution for jewelry design and manufacturing workflows. Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts and ultra-fast same-day rapid prototyping.

Figure 4

Ultra-fast and affordable 3D printing solution for jewelry design and manufacturing workflows. Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts and ultra-fast same-day rapid prototyping.

SLA 3D Printers

3D Systems—the inventor of Stereolithography (SLA) and the only SLA manufacturer offering the total solution with integrated hardware, software and materials fine-tuned to achieve renowned SLA parts quality—brings you legendary precision, repeatability and reliability in SLA 3D printers. SLA printers work with a wide range of materials, with a range of sizes and price points, which are designed for prototyping, end-use part production, casting patterns, molds, tooling, fixtures and medical models.

SLA 3D Printers

3D Systems—the inventor of Stereolithography (SLA) and the only SLA manufacturer offering the total solution with integrated hardware, software and materials fine-tuned to achieve renowned SLA parts quality—brings you legendary precision, repeatability and reliability in SLA 3D printers. SLA printers work with a wide range of materials, with a range of sizes and price points, which are designed for prototyping, end-use part production, casting patterns, molds, tooling, fixtures and medical models.

Brainstorm Your Solution

We help you find clarity in the crowded world of 3D printing and software. Start with Nota3d.

Book Appointment

Our favorite thing is to learn about you and your specific goals when it comes to 3D technology. We have various solutions and will help you find the right fit, even if it isn’t from us.

Contact Us

Call us

414-207-4404