Digital Dentistry | How SYNrG Labs Succeeds with 3D Printing

If you were to ask Brian Lindke 15 years ago what he thought about dental 3D printing, his answer would have been – “It will never be as good as we can do by hand.”

Today, he runs SYNrG Dental Labs, a company that has fully embraced the power of dental 3D printing.

So how and when did he make such a drastic leap into the unknown of 3D printing? In Brian’s own words, it was through the application of milling, or the subtractive process, that opened his eyes to the potential of 3D printing.

With over three decades of experience, Brian spent his early years developing surgical guides and denture teeth through the typical “analog” approach, as he likes to call it.

While milling did provide some improvement in their production time, it could only get them to 75-80% of the finished product. There was still quite a bit of labor after the fact, due to limited material options and lack of quality.

Once Brian was able to experience the process of milling and some of the disadvantages that come along with it, he was then able to see the potential of 3D printing. In his words, “printing made more sense.”

After starting down the path of 3D printing, Brian realized that instead of parts being 75-80% complete, they were closer to 95% complete. These parts only required minimal post-processing thanks to a smoother surface finish, specialty materials & much higher accuracy.

Brian outsourced most of the 3D printing early on. Little by little, he started moving things in-house, gradually adding small, consumer-level printers. While having more capabilities in-house was a good thing, Brian found that the “cheaper” printers didn’t produce the quality or speed needed. He knew he needed to add a professional-grade printer if he wanted to achieve any lasting success with this new digital way of doing things.

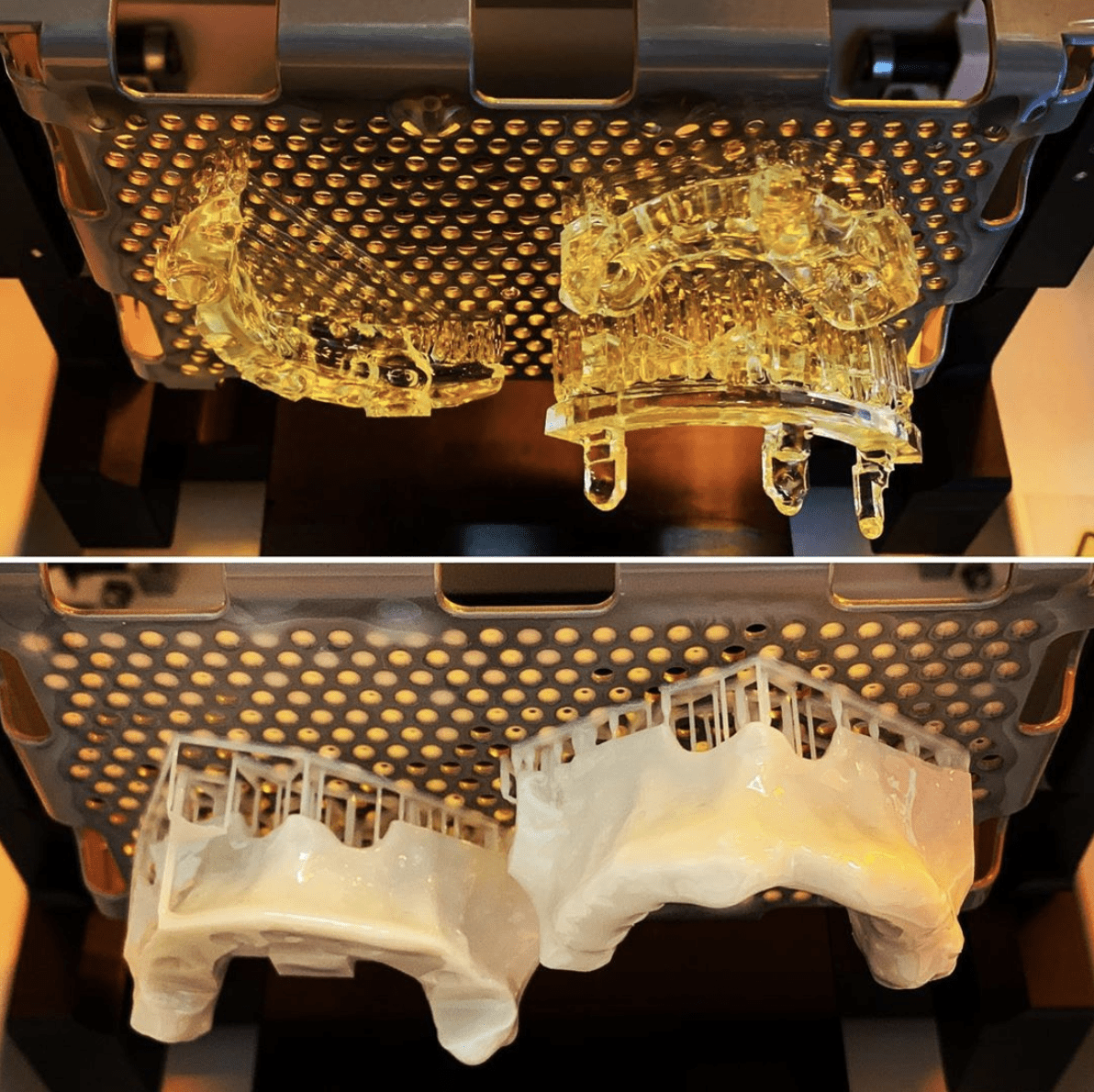

Already having a close relationship with 3D Systems, he started there – narrowing down his selection to the NextDent 5100, and it’s approved dental specific materials. Since 3D Systems uses a reseller channel, they gave Brian three choices of resellers. He interviewed all three and quickly decided to work with Jason Jarosch and the team at Nota3D.

When asked what the deciding factor was to work with Nota3D, his response was, “there was an instant sense of peace upon the initial conversation with Jason, the confidence in his knowledge of the technology and industry was huge.”

Brian knew he could lean on Nota3D’s expertise for the long term. In his opinion, “the ongoing support is more important than the initial purchase.”

Having a reseller that isn’t one dimensional, only focused on dental labs, has helped SYNrG think outside the box regarding how they can fully capitalize on their investment, which is now a total of three NextDent 5100 printers with plans to add more in the future.

What Brian and his company have been able to accomplish with their 3D printing lab is a complete paradigm shift from his own way of thinking 15 years prior. For their clients, time is money, and the print-on-demand capability is an efficient, expedited process.

What used to take 4-6 visits now only takes 1 or 2, lessening the patient’s inconvenience of multiple visits. Simultaneously, the reduction in chair time has opened the door to treat more patients, which increased revenue for the practice—making the ROI on the 3D printers faster than ever anticipated.

With the ongoing support from Nota3D, the team at SYNrG has been able to fine-tune their process. With one printer dedicated to volume prints, one to stacked prints, and one to on-demand prints like a single guide or model, their dental lab has become a well-oiled machine that has significantly contributed to their success and growth as a company.

When COVID-19 hit, Brian was able to take some time and apply his success to other ventures, starting the design-to-print company, Flow3D. This has given him the opportunity to serve a broader range of industries.

Technology is an ever-changing commodity and SYNrG has been able to adapt and evolve with it. Being able to use their vast knowledge and combining it with the expertise of a company like Nota3D, has given them the edge to succeed and grow. It’s exciting to see what the future holds for Brian and his team.

Want to learn more about the NextDent 5100?

Share on Social Media

Share on facebook

Facebook

Share on twitter

Twitter

Share on linkedin

LinkedIn