Effective Strategies for Overcoming Challenges and Unlocking Manufacturing Potential

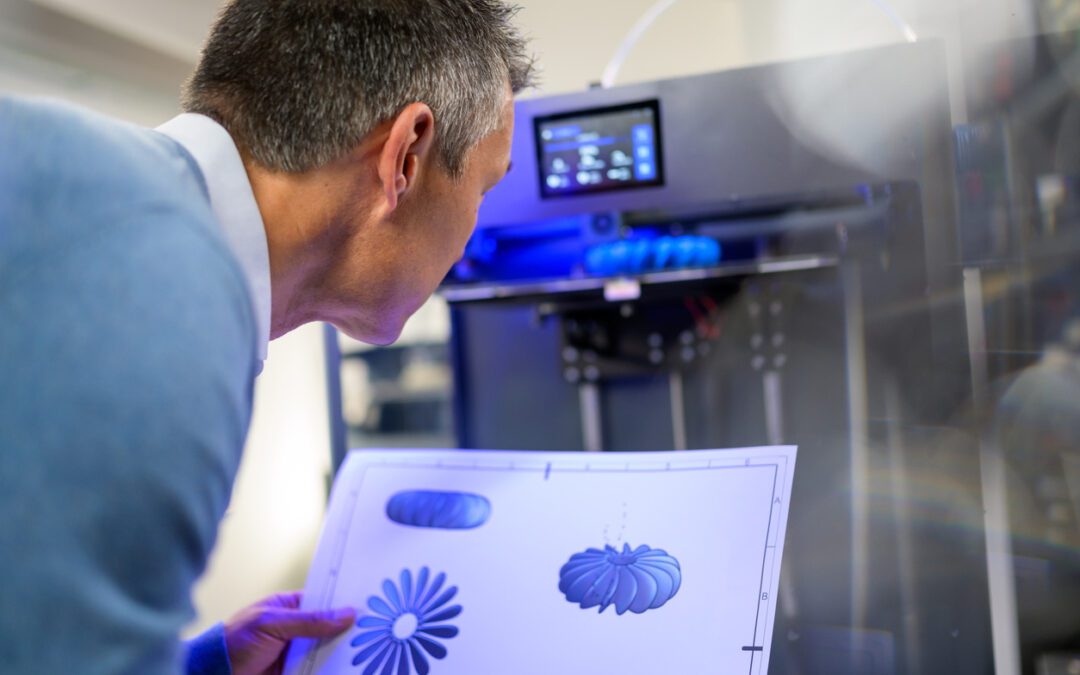

The innovation and versatility of plastic-based manufacturing through 3D printing have opened doors to endless possibilities. One of the key advantages lies in the flexibility it offers, allowing for the creation of intricate designs and complex geometries that were previously unattainable through traditional manufacturing methods. This has significantly impacted industries such as aerospace, automotive, healthcare, consumer goods, and more.

From rapid prototyping to intricate product designs, plastic 3D printing has revolutionized industries. By swiftly translating conceptual designs into physical prototypes, businesses can effectively visualize and validate their ideas before committing to large-scale production, thereby saving both time and resources.

Despite these advantages, the technology isn’t devoid of challenges. The intricacies involved in achieving consistent quality and efficiency demand meticulous attention. Factors such as material selection, print settings, maintenance, and post-processing techniques significantly influence the final output. Navigating these hurdles is crucial for ensuring consistent quality and efficiency. Let’s delve into some common challenges faced in plastic 3D printing and explore effective strategies to overcome them.

Warping and Cracking:

Challenge: Warping and cracking occur due to uneven cooling, leading to distortions or fractures in printed objects, especially in larger prints or with certain plastics like ABS.

Solution: Address this issue by optimizing the print bed temperature, employing a heated enclosure, and utilizing proper cooling mechanisms. Additionally, adjusting the design to minimize large flat surfaces and incorporating fillets or chamfers can reduce stress points, minimizing warping and cracking.

Poor Adhesion Between Layers:

Challenge: Inadequate bonding between printed layers can weaken the structural integrity of the object.

Solution: Ensure the print bed is level and clean to promote better adhesion. Adjusting printing parameters like temperature, print speed, and layer height can also improve layer bonding. Experimenting with different infill patterns and utilizing bonding agents or adhesives may further enhance adhesion.

Nozzle Clogging:

Challenge: Filament residue buildup can cause nozzle clogging, disrupting the printing process and leading to imperfect prints.

Solution: Regular maintenance is key. Keep the nozzle clean by performing routine checks and using appropriate cleaning tools. Adjusting temperature settings for different filament types and using high-quality filaments can help reduce the likelihood of clogs.

Quality Control and Consistency:

Challenge: Maintaining consistent print quality across multiple prints is crucial but challenging.

Solution: Implement stringent quality control measures by calibrating the printer regularly, using quality filament, and keeping detailed records of print settings for different materials and models. Invest in monitoring systems and software to detect deviations in print quality early on.

Material Selection and Compatibility:

Challenge: Not all plastics are suitable for every 3D printing application, and selecting the right material can be complex.

Solution: Conduct thorough research on material properties, considering factors like strength, flexibility, heat resistance, and cost. Perform material compatibility tests and consult with material suppliers to ensure the chosen filament aligns with the intended use of the printed object.

Post-Processing and Finishing:

Challenge: Achieving desired surface finishes and textures post-printing can be demanding.

Solution: Experiment with different post-processing techniques like sanding, polishing, or chemical treatments. Utilize specialized equipment for smoothing or finishing, and consider secondary processes like painting or coating for desired aesthetics.

Design Limitations and Support Structures:

Challenge: Intricate designs or overhangs often require support structures, affecting print quality and design flexibility.

Solution: Optimize designs to minimize overhangs and use support structures strategically. Explore software tools that generate efficient support structures while minimizing material usage. Experiment with soluble support materials for easier removal.

Environmental Impact and Sustainability:

Challenge: Plastic waste generated from failed prints or support structures raises environmental concerns.

Solution: Embrace sustainable practices by recycling or reusing failed prints and support materials whenever possible. Explore eco-friendly filament options made from recycled materials or biodegradable plastics to reduce environmental impact.

Scaling Production and Time Constraints:

Challenge: Balancing increased demand with limited production time can be a significant hurdle.

Solution: Implement efficient workflows and optimize printing schedules. Consider investing in multiple printers or higher-capacity machines to scale production. Utilize batch printing and automation wherever feasible to reduce turnaround times.

Efforts to overcome these hurdles not only ensure the delivery of high-quality products but also contribute to enhancing customer satisfaction and building a reputation for reliability and excellence in the industry. Adapting to emerging technologies, materials, and methodologies will be instrumental in overcoming challenges and thriving in the ever-evolving world of plastic 3D printing.

For a 3D printing business aiming to deliver superior products consistently, navigating these challenges is paramount. Ensuring a streamlined workflow from design to printing and post-processing stages becomes crucial. It involves comprehensive understanding and fine-tuning of printer settings, meticulous calibration, and continuous monitoring of print quality. As the technology evolves, staying abreast of the latest advancements and implementing them effectively is essential for maintaining a competitive edge in the market.

Nota3D works tirelessly to unlock the vast potential and possibilities that plastic-based 3D printing offers across diverse sectors. Our team is the most responsive in the industry—solving issues, developing solutions, and delivering materials faster than anyone else on the market. We work tirelessly to bring you what you need when you need it. Visit our website or contact us to get started.