Figure 4 Modular

SCALABLE, SEMI-AUTOMATED 3D MANUFACTURING SOLUTION DESIGNED TO SCALE WITH GROWTH

SCALABLE, SEMI-AUTOMATED 3D MANUFACTURING SOLUTION DESIGNED TO SCALE WITH GROWTH

Expandable capacity up to 24 print engines. Automated job management and queuing, automated material delivery, and centralized post-processing. Same-day prototyping and direct 3D production up to 10,000 parts per month. Each printer can run different materials and different jobs as part of a single high throughput line.

Scalable 3D Printing Platform

Figure 4® Modular is a scalable, semi-automated 3D production solution that grows with your business, enabling capacity to meet your present and future needs, up to 10,000 parts per month, for unprecedented manufacturing agility. With an expandable capacity of up to 24 print engines, automated job management and queuing automatic material delivery, and centralized post-processing, Figure 4 Modular’s end-to-end digital manufacturing workflow is ideal for low to mid-volume production and bridge manufacturing. In addition, each printer can run different materials and jobs as part of a single high throughput line serving many parts being produced.

Upgradeable 3D production designed to scale with growth

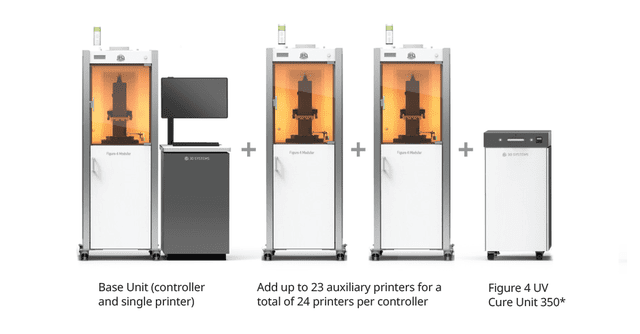

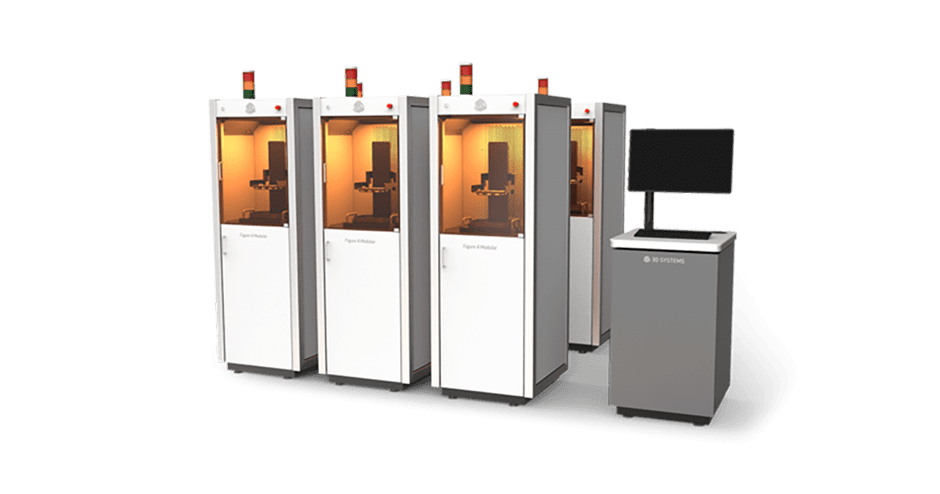

Modular Scalability

The base configuration of Figure 4 Modular is comprised of a single printer and a central controller. This can be easily scaled to up to 24 printer modules on a single controller, with layout configuration flexibility, empowering production to rapidly multiply without disruption to the shop floor.

Low Total Cost of Operations

Figure 4 Modular enables companies to move directly into manufacturing from a digital CAD file, bypassing tooling costs, and delays to start delivering final parts immediately. This semi-automated solution reduces labor through automated job management, queuing, and an automated material feed system.

Unparalleled Flexibility

Figure 4 Modular printers enable the simultaneous production of various part sizes and shapes in multiple materials for a diverse range of parts for production and prototyping.

End-to-End Productivity

Fast and easy print jobs preparation, ultra-fast print speeds, post-curing in minutes instead of hours and production management ensure high parts throughput with high accuracy and repeatability.

Broad Range of Materials

3D Systems’ Material Design Center has over 30 years of proven R&D experience and process development expertise. The broad and expanding range of materials available for Figure 4 Modular addresses a wide variety of applications needs, for functional prototyping, direct production of end-use parts, molding and casting, and includes rigid and durable thermoplastic-like, rubber-like, heat resistant, and biocompatible capable materials.

Revolutionizing Manufacturing

Scalable, semi-automated 3D manufacturing solution designed to grow with your prototyping and production needs. They are enabling companies to move directly into production from digital CAD files to delivering final parts immediately.

Speed and versatility

Same-day prototyping and direct 3D production of up to 10,000 parts per month. In addition, each printer can run different materials and jobs as part of a single high throughput line serving many parts being produced.