Revolutionizing Industries With Cutting Edge Technology

The advent of 3D printing with metal has revolutionized various industries, unlocking new possibilities and transforming traditional manufacturing processes. This cutting-edge technology holds immense importance due to its unique advantages. First and foremost, it enables the creation of complex and intricate designs that were previously impossible to achieve with conventional methods. This capability not only enhances product performance but also promotes innovative solutions in aerospace, automotive, and medical sectors.

Additionally, 3D metal printing allows for the production of customized and personalized components, reducing material waste and optimizing resource utilization. This environmentally-friendly aspect aligns with the growing emphasis on sustainable practices in modern manufacturing. Moreover, the speed and efficiency of metal 3D printing have significantly reduced production times, enabling rapid prototyping and accelerated product development cycles. As this technology continues to advance, its potential for cost-effectiveness and broad-scale application will continue to grow, making it an indispensable tool for shaping the future of manufacturing and engineering.

As this innovative technology continues to evolve, designers and engineers must adapt their approach to fully harness its potential. In this blog, we will explore 8 critical design considerations essential for successful metal 3D printing, empowering businesses to unlock new possibilities and achieve exceptional results.

1.Understanding Metal 3D Printing Technologies

Before delving into the design process, it is crucial to comprehend the different metal 3D printing technologies available. Common methods include Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Electron Beam Melting (EBM). Each technology has unique capabilities, layer thicknesses, and material compatibility. Choosing the right method that aligns with the desired outcome is fundamental to the design process.

- Selective Laser Melting (SLM): Selective Laser Melting is a powder-based 3D printing process that involves melting and fusing metal powder using a high-powered laser. The metal powder is spread layer by layer, and the laser selectively fuses the powder particles together based on the 3D model’s design. As each layer is fused, the build platform moves down, and a new layer of powder is applied, repeating the process until the entire object is formed. SLM is known for producing highly dense and fully functional metal parts, making it suitable for applications that require high precision and mechanical strength.

- Direct Metal Laser Sintering (DMLS): Direct Metal Laser Sintering is similar to SLM but operates at a lower temperature. Instead of fully melting the metal powder, DMLS uses a laser to sinter the particles, causing them to fuse together without reaching a complete molten state. This process results in a slightly porous structure, which may require additional post-processing steps for improved density and strength. DMLS is commonly used for manufacturing prototypes and end-use parts with complex geometries in aerospace, automotive, and medical industries.

- Electron Beam Melting (EBM): Electron Beam Melting is another powder-based metal 3D printing technique that utilizes an electron beam to melt and fuse metal powder. Unlike lasers, which can be used in selective laser melting, the electron beam is more powerful and can produce higher energy densities. EBM is performed in a vacuum environment to avoid the effects of air on the electron beam. The process enables faster printing speeds and is ideal for producing large, dense metal components for critical applications like aerospace and orthopedic implants.

The key differences between these 3D printing methods with metal lie in their heating mechanisms, the energy source used (laser or electron beam), and the resulting properties of the printed parts (porosity, mechanical strength). Each method has its advantages and is suitable for specific applications, allowing manufacturers to choose the most appropriate technique based on their requirements and desired outcomes.

2. Designing for Additive Manufacturing (DFAM)

Designing for Additive Manufacturing (DFAM) represents a transformative shift in the manufacturing landscape, departing from traditional subtractive methods. Metal 3D printing opens up a realm of possibilities, inviting engineers and designers to unleash their creativity by capitalizing on the unique capabilities of this technology. Embracing metal 3D printing means breaking free from the constraints imposed by conventional manufacturing techniques, enabling the realization of unprecedented designs.

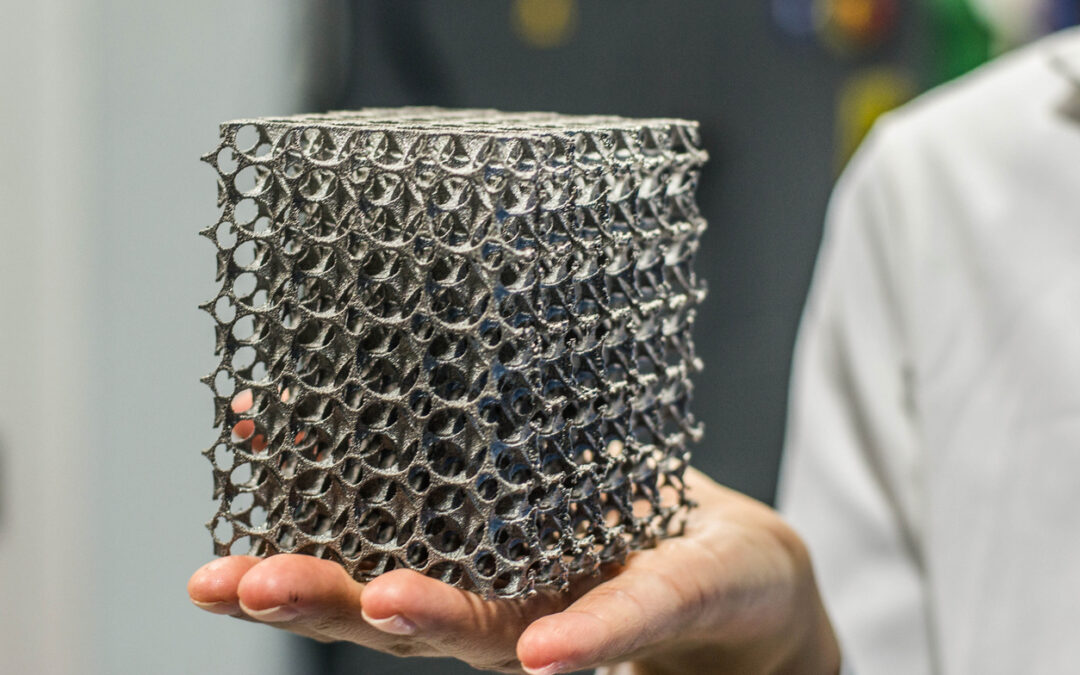

The flexibility of this process allows for the creation of organic shapes, intricate geometries, and lightweight structures that were once inconceivable or too challenging to fabricate. With DFAM, designers can optimize parts for specific functions and create components that are tailored to exact specifications, thereby reducing material waste and minimizing the need for assembly of multiple parts. Through iterative prototyping and simulations, designers can optimize designs, reducing trial-and-error cycles and accelerating the product development process.

3. Optimizing Part Orientation

Part orientation significantly impacts the mechanical properties and surface finish of metal 3D printed components. Designers must carefully consider how the part will be positioned during the printing process to maximize its mechanical properties and surface finish. Proper orientation helps to minimize the occurrence of residual stresses, which can lead to warping or deformation during and after printing. By strategically positioning the part, designers can reduce the need for excessive support structures, reducing post-processing efforts and material wastage. A well-thought-out orientation can lead to superior surface quality, reducing the need for additional finishing steps. However, achieving the ideal part orientation requires a delicate balance between various factors. Optimal orientation might improve strength and performance but could potentially increase the build time, impacting production efficiency and costs.

Designers must also consider material usage, ensuring that the chosen orientation does not result in excessive material consumption, which could affect the overall economics of the 3D printing process. By carefully weighing these trade-offs and leveraging simulation tools, designers can find the sweet spot that results in a successful metal part with optimal mechanical properties, excellent surface finish, and efficient production.

4. Material Selection and Properties

Selecting the appropriate metal alloy is crucial for the functionality and performance of the final part. Different metals exhibit varying thermal conductivities, melting points, and mechanical properties. Understanding these material characteristics will help designers make informed decisions, ensuring the desired properties are achieved in the finished product.

Several types of metals and metal alloys are commonly used in 3D printing with metals, each offering unique properties and characteristics. Some of the most common types of metals used in metal additive manufacturing include:

- Stainless steel is widely utilized in 3D printing due to its corrosion resistance, high strength, and affordability. It finds applications in industries such as automotive, aerospace, and consumer goods.

- Titanium is a lightweight, strong, and biocompatible metal used extensively in the medical and aerospace industries. It is known for its excellent strength-to-weight ratio and resistance to corrosion.

- Aluminum is another lightweight metal commonly used in 3D printing. It offers good strength, thermal conductivity, and is utilized in industries such as aerospace, automotive, and consumer electronics.

- Nickel alloys, such as Inconel and Hastelloy, are known for their exceptional high-temperature resistance and corrosion resistance. They find applications in industries like aerospace, energy, and chemical processing.

- Cobalt-chrome alloys, such as CoCrMo, are commonly used in medical and dental applications due to their biocompatibility and excellent mechanical properties.

- Copper is utilized for its excellent electrical and thermal conductivity. It finds applications in electronics, heat exchangers, and electrical components.

- Precious metals like gold and silver are also used in metal additive manufacturing, particularly in the production of jewelry, decorative objects, and high-end consumer goods.

5. Wall Thickness and Feature Size

Metal 3D printing has undoubtedly opened up new horizons for creating intricate and delicate features in designs, as well as thin walls that were once challenging to achieve through traditional manufacturing methods. However, designers must tread carefully, as the unique capabilities of metal 3D printing also come with certain limitations that must be considered. One critical factor is the wall thickness of the components being printed. While it may be tempting to push the boundaries of design complexity, insufficient wall thickness can lead to print failures or compromise the mechanical properties of the final part.

It is imperative to strike a harmonious balance between design intricacy and manufacturability. This involves understanding the capabilities and constraints of the chosen metal 3D printing technology and the material being used. By carefully evaluating the intended application and structural requirements, designers can optimize the wall thickness to ensure that the 3D printed parts meet the desired functionality, strength, and reliability while still achieving the desired intricate features. Collaboration between designers, engineers, and 3D printing experts is instrumental in navigating these challenges and ensuring that the end product is both visually captivating and structurally robust.

6. Designing for Post-Processing

Metal 3D printing, while offering numerous advantages, often necessitates post-processing to achieve the desired final form and functional characteristics of the printed parts. Designers must be mindful of these post-processing requirements from the outset of the design phase. One crucial aspect is the removal of support structures used during printing to ensure the part’s stability. Designers should consider how to design support structures strategically, making them easier to remove and minimizing the need for extensive manual intervention. Additionally, heat treatment may be necessary to improve the mechanical properties and relieve residual stresses within the part, especially for certain metal alloys. Integrating heat treatment considerations into the design can optimize the component’s performance. Moreover, surface finishing, such as machining, polishing, or coating, is often essential to achieve the desired surface quality and functional characteristics.

By factoring in these post-processing steps during the design stage, designers can anticipate the specific requirements and ensure that the 3D printed parts can smoothly transition from the printing stage to the final product, streamlining the overall production process and reducing the need for costly and time-consuming adjustments after printing. This proactive approach enhances efficiency, reduces material waste, and ultimately leads to the creation of high-quality metal parts that meet or exceed the desired specifications.

7. Avoiding Thermal Distortions

In metal 3D printing, dealing with thermal distortions presents a significant and common challenge, particularly when printing large and complex parts. The process of metal 3D printing involves melting and solidifying metal powder layer by layer, subjecting the material to intense localized heat. This heat can cause uneven temperature distribution, leading to thermal gradients within the part. As a result, certain areas cool and contract at different rates, potentially causing warping, cracking, or deformation of the printed component. To address this issue, designers must have a deep understanding of the thermal behavior of the chosen metal material. By carefully analyzing the material’s thermal properties, including its coefficient of thermal expansion and specific heat capacity, designers can anticipate how the material will respond to the printing process.

Armed with this knowledge, designers can then optimize the part’s design to minimize the accumulation of heat in critical regions. This can be achieved by strategically placing additional supporting structures or heat sinks, using lattice structures to dissipate heat, or adjusting the printing parameters to control the heat input. By taking these preventive measures, designers can significantly reduce the likelihood of thermal distortions and ensure the successful production of high-quality metal 3D printed parts, even in the face of challenging geometries and large-scale manufacturing.

8. Implementing Support Structures

Support structures play a vital role in maintaining the stability of overhanging features and complex geometries during the printing process. As metal powders are selectively fused by the laser or electron beam, any overhangs without support would collapse during printing, compromising the integrity of the final part. Designers must carefully consider the placement and design of support structures to strike a delicate balance. While supports are essential for successful printing, they can also leave unwanted marks or surface irregularities on the final part. Strategic placement of supports can help minimize their impact on the critical surfaces of the component. Moreover, designers should consider the ease of support removal, as precision and care are necessary to ensure that no damage is done to the printed part during this process.

Some advanced software tools and simulation techniques can aid designers in optimizing support structures, making them easier to remove while still ensuring proper anchoring during printing. By effectively managing support structures, designers can achieve high-quality metal 3D printed parts with intricate features and overhangs, meeting the desired specifications without compromising the overall integrity of the component.

As metal 3D printing continues to redefine manufacturing possibilities, mastering the art of designing for additive manufacturing is becoming increasingly important. Embracing the freedom and flexibility that metal 3D printing offers allows designers and engineers to create groundbreaking solutions previously unattainable through conventional methods. By understanding the intricacies of different metal 3D printing technologies, optimizing part orientation, selecting suitable materials, and integrating post-processing considerations, businesses can achieve remarkable success in metal 3D printing. Embrace the revolution of additive manufacturing, and witness the transformation of design concepts into tangible metal masterpieces.

At Nota3D, we pride ourselves on being a resource for our customers to continuously develop internal processes, drive innovation, and increase efficiency by utilizing the finest additive manufacturing technology. We achieve this by being a team of experts for you to partner with and depend on. We help you find clarity in the crowded world of 3D printing and software. Start with Nota3d.