Projet MJP 2500 IC

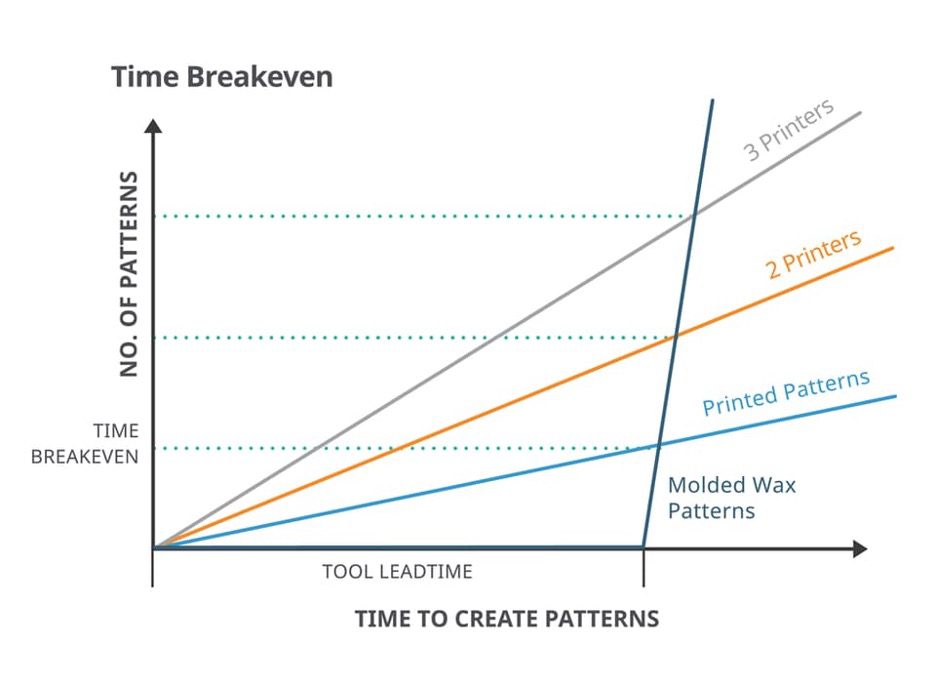

Unmatched Turnaround Time

Save weeks on wax pattern production with tool-less RealWax™ MultiJet Printing and accelerate time-to-market. The ProJet® MJP 2500 IC enables a digital workflow with direct wax pattern printing, increasing productivity and enabling fast time-to-part for premium service delivery to customers. With fast wax pattern production, short cycle times capability, and 24/7 operation, you can rely on the ProJet MJP 2500 IC output and improved casting room efficiency.

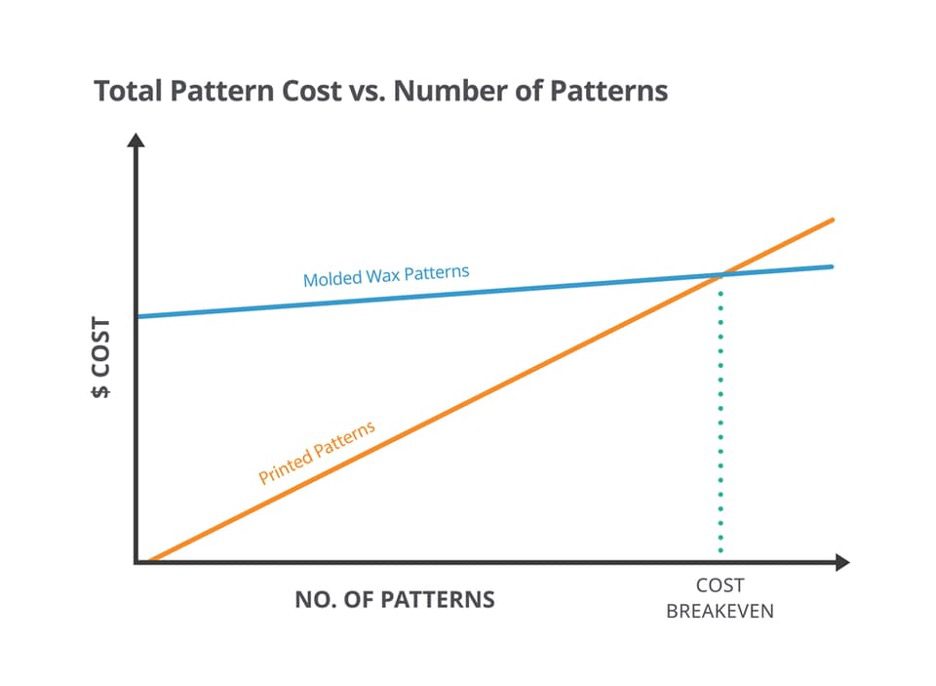

At a Fraction of Tooling Costs

Have hundreds of your small to medium-size patterns in hand more quickly and less expensively compared to the time and cost to build and run a traditional injection tool. If design changes are needed, the benefits just compound. The ProJet MJP 2500 IC leverages existing investment casting processes and equipment. Expect fast amortization and high returns on investment with this unique industrial wax pattern 3D printing solution.

Ultimate Design Freedom

With digital design, you can produce wax patterns for parts that take advantage of topology optimization, lightweight, and part consolidation. The ProJet MJP 2500 IC frees you to produce multiples of a complex part geometry or simultaneously make design variants, all while delivering better performing, more cost-effective components in a fraction of the time of traditional alternatives.

Best Casting Reliability

VisiJet® M2 ICast 100% wax material emulates standard casting waxes’ melt and burn-out characteristics. This RealWax 3D printing material drops seamlessly into existing wax casting processes. MultiJet Printed patterns hold tight tolerances, ideal for complex precision metal components manufacturing with reduced or no finishing work.

• High fidelity and repeatability

• Smooth surfaces

• Sharp edges

• Extreme fine details

Optimized Resources

Streamline your file-to-pattern workflow with the advanced 3D Sprint® software capabilities for preparing and managing the additive manufacturing process, unattended high-speed printing, and a defined and controlled post-process methodology. MultiJet Printing’s ease-of-use and dependable process ensure reliable performance, yield, and results.

Applications

- Low to mid-volume production

- Bridge manufacturing

- Instant design validation with multiple version testing

- Customized metal components

- Parts consolidation into higher performing units with no assembly labor/costs

- Higher part complexity not achieved through traditional molding

- Topology optimization and lightweighting

- Rapid metal casting prototyping

Benefits

- Time and costs elimination of designing and manufacturing of tooling

- Patterns within hours vs. weeks for premium service

- Hundreds of patterns by the time required for tooling

- Elimination of mold storage costs

- Seamless fit in existing investment casting processes

- Ideal for small to medium size patterns

- File-to-pattern ease-of-use

- Minimal, simple post-processing

- Reliable performance, yield, and results

- No additional client or prep software required

Tech Specs

- MultiJet Printing technology

- Net build volume (xyz): 11.6 x 8.3 x 5.6 in (294 x 211 x 144 mm)

- 100% wax VisiJet M2 ICast material

- Volumetric print speed up to 12.5 in3 /hour (205 cm3 /hour)

- Short cycle times capability

- Maximized full print volume for long, unattended builds

- Streamlined file-to-print workflow with the 3D Sprint software capabilities

- Defined post-processing methodology

- High Definition (HD) build mode for best surface quality

- High Definition Fractal (HDF) build mode for easier support removal

- VisiJet Support Wax Remover (VSWR) post-processing fluid

- Cloud connectivity for predictive and prompt service with 3D Connect™