SLS 380

SLS Material Properties & Uses

Nylon PA 12

Strong polyamide 12 thermoplastics that can replace traditionally injection molded articles; includes food-grade, medical-grade, and flame-retardant capable options.

Filled Nylons / PA

Engineered for greater end-use part performance, these materials are developed with glass, aluminum, or mineral fiber fillers to offer a range of advanced properties in terms of stiffness, temperature resistance, strength, and surface finish.

Nylon / PA 11

Impact-resistant polyamide 11 thermoplastics that offer molded-part performance in harsh environments; ideal for snap-fits and living hinges with the flexibility to bounce back to the original shape.

Elastomeric Thermoplastics

Rubber-like flexibility for prototypes and production parts with excellent memory, tear, and abrasion resistance.

Castable Polystyrene

Great for sacrificial patterns for prototype metal castings and low to medium production runs without tooling.

Why Use SLS?

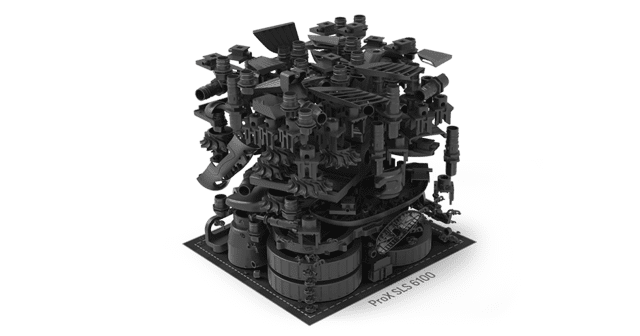

High Speed and Throughput

Large SLS build capacities paired with fast build times, high-density nesting, and no support structures help you maximize every print for more parts, sooner.

Best-In-Class Part Quality

Side-by-side comparison testing shows 3D Systems SLS printers provide best-in-class part quality.* Get superior accuracy, part resolution, edge definition, and surface finish with 3D Systems’ SLS solutions.

* Same part file printed on ProX SLS 6100 in DuraForm ProX PA compared to a competitive system in PA 12

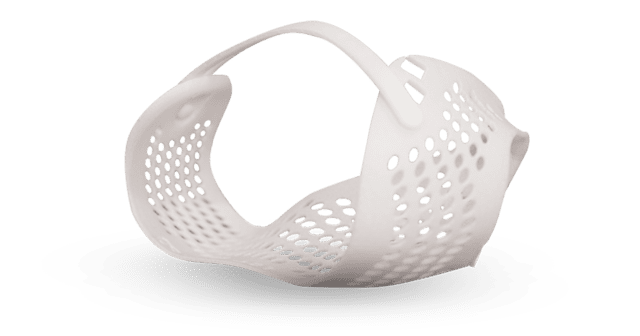

Functional Design

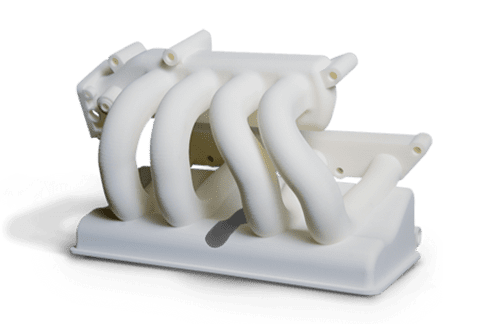

As a self-supporting build methodology, SLS enables the production of complex geometries, such as monolithic designs, lightweight components, and mass-customized products, that could not be manufactured any other way.

Low Part & Ownership Costs

The features and capabilities of 3D Systems’ SLS deliver up to 20% lower operational costs compared to similar printers. These include automated production tools, high throughput, material efficiency, and repeatability, just to name a few.

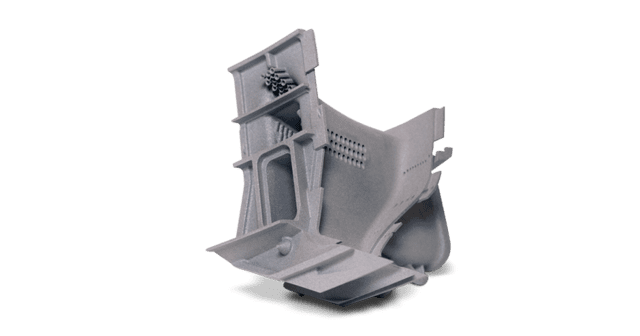

Robust, Performance Parts

SLS technology produces tough and durable parts that excel in high-performance prototyping and end-use applications. 3D Systems’ DuraForm® SLS materials have been optimized, validated, and tested to ensure quality, with uniform 3D mechanical properties.

Broad SLS Materials Selection

Manufacture with true nylon materials that answer your application requirements. Whether you need toughness, heat resistance, flame retardancy, flexibility, or food-grade and medical-grade options, the 3D Systems SLS materials portfolio has you covered.

Application

- Impact and temperature resistant durable parts

- Covers, housings, enclosures

- Jigs and fixtures

- Reduced weight production parts

- Knobs, handles and other dashboard/interior parts

- Parts with snap fits and living hinges

- Machinery components

- Complex duct work

Benefits

- Exceptional surface finish and resolution

- Prints parts that others struggle to print

- Minimal waste of materials

- Consistently high accuracy parts even on first-time builds

- Ease of use ‒ intuitive workflow

Tech Specs

- Selective laser sintering (SLS) technology

- Max build envelope capacity (W x D x H): 15 x 13 x 18 in (381 x 330 x 460 mm)

- Consistent mechanical properties

- High production speed for its class of 2.7 l/hr

- Streamlined production control, including 3D Sprint® integrated additive manufacturing software, fully automated powder handling and optional 3D Connect capability

- Automated 3D part nesting

- Maximized build volume and density