DLP (Digital Light Processing)

Makes Production A Reality

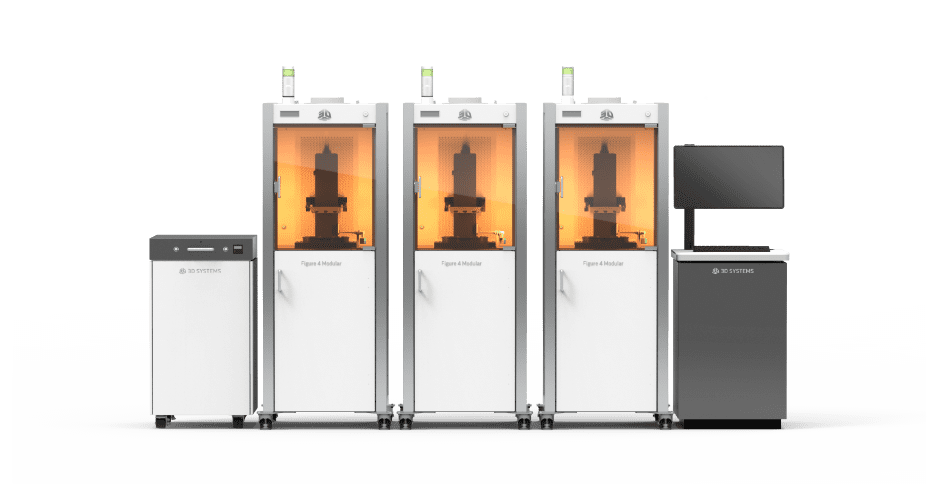

MAKING 3D PRODUCTION REAL WITH SCALABLE, MODULAR FACTORY SOLUTIONS

Figure 4 delivers ultra-fast additive manufacturing technology with systems that offer the expandable capacity to meet your present and future needs. With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts, as well as ultra-fast same-day rapid prototyping.

Figure 4 Stand-Alone

Affordable industrial-grade solution for lower cost production parts

Figure 4 Modular

Upgradeable 3D production designed to scale with growth

NextDent 5100

Powered by Figure 4® technology, the NextDent™ 5100 facilitates high-speed 3D printing for the production of dental appliances and sacrificial castings.